A pattern may be defined as a model or replica of desired casting which when moulded in sand forms an impression called mould. The mould when filled with molten metal forms casting after solidification of the poured metal. The quality and accuracy of casting depends upon the pattern making. The pattern may be made of wood, metal (Cast iron, Brass, Aluminum and its alloy, White metal), plaster, plastics and wax.

A pattern is always made larger than the required size of casting considering the various allowances. The following allowances are usually provided in a pattern:

1. Shrinkage or contraction allowance

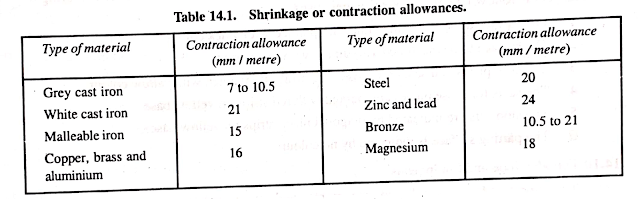

The various metals used for casting contract after solidification in the mould. Since the contraction is different for different metals, therefore the corresponding allowances also differ. The following table shows the contraction allowances for castings of different materials in sand moulds.

Note: If a pattern is first made of wood and then from some other metal, then double allowances are provided on the wooden pattern. For example, if an aluminum pattern made from a wooden master pattern is to be used for grey iron castings, then a total shrinkage allowance of 26 mm I meter (16 mm I meter for aluminum and 10 mm I meter for grey iron), may be allowed on the pattern.

2. Draft allowance

It is a taper which is given to all the vertical walls of the pattern for easy and clean withdrawal of the pattern from the sand without damaging the mould cavity. It may be expressed in millimeters per meter on a side or in degrees. The amount of taper varies with the type of patterns. The wooden patterns require more taper than metal patterns because of the greater frictional resistance of the wooden surfaces.

3. Finish or machining allowance

This allowance is provided on the pattern if the casting is to be machined. This allowance is given in addition to shrinkage allowance. The amount of this allowance varies from 1.6 to 12.5 mm which depends upon the type of casting metal, size and shape of casting, method of casting used, method of machining to be employed and the degree of finish required. The ferrous metals require more machining allowance than nonferrous metals.

4. Distortion or camber allowance

This allowance is provided on patterns used for castings of such design in which the contraction is not uniform throughout.

5. Rapping or shaking allowance

This allowance is provided in the pattern to compensate for the rapping of mould because the pattern is to be rapped before removing it from the mould.

Type of Patterns

The common types of patterns are as follows:

- Solid or single piece pattern

- Split pattern (two piece or multipiece pattern)

- Match plate pattern

- Cope and drag pattern

- Loose piece pattern

- Gated pattern

- Sweep pattern

- Skeleton pattern

- Shell pattern

- Segmental pattern

- Follow board pattern

- Lagged-up pattern

- Left and right hand pattern.

Note: When a pattern is made in three parts, the bottom part is known as drag, the top part is called cope while the middle one is called cheek.

Core Boxes

The core boxes, like patterns, may be made either of wood or metal. The core boxes are used for a casting requiring cores. Wood is generally used for making core boxes, but metal core boxes are preferred where cores are to be prepared in large numbers on mass production basis. Following are the various types of core boxes commonly used:

- Half core box

- Dump core box

- Split core box

- Strickle core box

- Right and left hand core box

- Loose piece core box

- Gange core box.

The important parts of a pattern and core box are painted with different colors for the identification of their different parts. Though there is no universally accepted standard for coloring the surfaces, yet the following colour code is widely used:

- The surface to be left unmachined are painted with black colour.

- The surface to be machined are painted with red colour.

- The core prints and seats for loose core prints are painted with yellow colour.

- The seats for loose pieces are marked with red strips on yellow base.

- The stop offs are indicated by diagonal black strips on yellow base.

- The parting surface is indicated by no colour.

No comments:

Post a Comment