Wind turbines are a big part of India’s path to renewable energy generation and not many people even know how important they are or how much power they can generate yearly.

Not only that, but not many even know how important slip rings are for the engineering of wind turbines and how they played a crucial role in making the largest wind turbine in India.

In this article, you’ll learn everything about India’s power generation from renewable sources, how important wind turbines are, and also how important slip rings are in the engineering of these wind turbines, so keep on reading!

Wind Turbines and Its Use in India

India manages to increase the generation of electricity from renewable sources each year with the help of wind turbines and they have the fourth largest wind power capacity in the world.

The total capacity includes 40.35 GW and the best thing is that India manufactures its own wind turbines without outsourcing any part of it outside of India.

Not only is Suzlon Energy Limited one of the biggest manufacturers of wind turbines in India, but they’re also available in 30 countries worldwide.

Therefore, wind turbines and renewable energy make up a total of 10% of India’s power generation capacity, it is still on the increase and it is still making a decent part of the country’s capacity.

In no time, India will be heading to producing 40% or more of its power generation capacity, just like China and USA are doing, but on the bright side, there are only 3 countries ahead of India.

This means that India is on the right track and with the proper wind turbines, and down below, you’ll be able to learn more about wind turbines that will help India’s economy yet will also save the planet at the same time.

What are Slip Rings and How do they Function

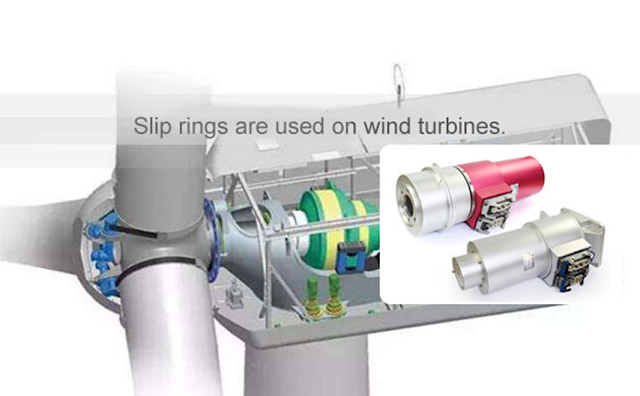

Slip rings are a small device that is often overlooked, but it plays an important role across many industries and it is featured in a wide range of devices and machines.

It is a device that consists of only a couple of parts where two main components include the ring and the brushes (or wipers) that are placed on the inside of the ring.

The main slip ring’s function was intended to solve a wire winding problem in devices and machines that feature a rotary part, as well as a stationary part.

However, while they remove wires from the joints and remove the hazard by still providing a connection between the rotary and stationary part, slip rings can also transmit an electrical signal, power, data, and even fluid, coolant, water, or other mediums.

While the rotary part rotates and since it’s connected to the slip ring, either ring (outer part) or the brushes (inner part) rotates and creates a brush contact that helps transmit all of the above while eliminating wires from the joints.

With so many different slip ring types, all sorts of mediums can be transmitted from the rotary to a stationary part of a device while establishing a contact.

Slip Rings’ Use in Wind Turbines

Slip rings are used in a couple of places inside wind turbines to help with the transfer of kinetic energy from the top (blades), to the rotor that’s connected to the generator which produces electric energy.

Starting from the top, slip rings are used right at the joint where the blades of the wind turbine meet the rotor and where the rotation is required to keep the kinetic energy moving down the rotor.

Right there, the slip ring helps ensure the contact between the blades and the rotor, but it is also responsible for limiting the blades’ rotational speed. Slip rings actually help prevent wind turbine blades from spinning too fast in case of strong winds since that could damage the wind turbine.

However, slip rings are also used near the bottom of wind turbines where the rotor meets the generator. The slip ring helps establish a connection between the rotational and stationary parts, but also adds resistance to the generator that produces electrical power from a renewable source.

Moflon is one of the most established manufacturers of slip rings for wind turbine use, but besides that, they also produce various slip rings that fit aviation, aerospace use, automation, robotics, and even health imaging equipment.

On top of that, Moflon also produces custom slip ring solutions for customers who have specific needs, and yet slip rings would fit well to solve the need.

Benefits of Slip Rings for India’s Energy from Renewable Source

Without slip rings, the whole movement of rotating parts of a wind turbine would be really tricky to connect and control successfully, especially to prevent blades from spinning too fast.

However, other than providing a great solution to remove wires in the joints, transfer the kinetic energy, and even help the generator produce electric energy from a renewable source which is the wind, slip rings are as important as some other major components.

Even though slip rings are tiny devices in comparison to other components of a wind turbine, they’re as crucial and they play an important role.

Often overlooked, slip rings can actually help sustain the wind turbine’s energy, create green jobs since they need maintenance as well, and generally, in combination with the benefits of wind turbines as a whole, they contribute to the environment by reducing the energy made from non-renewable sources.

And if there were no slip rings, wind turbines might have to function differently, especially the part where the blades have to be limited in order not to over spin and be a hazard to other components it’s attached to.

Conclusion

Even though India generates only about 10% of energy from a renewable source, it is the 4th biggest contributor on the planet and it’s still on the rise to achieving greater numbers.

Not many know what slip rings are and how they function, but if you come across them earlier, you might not even know that they play an important part in the wind turbine’s design.

Even though slip rings are fairly simple to understand in theory, they are a solution to the main problem, and yet they have additional benefits that can fit so many industries and machines other than wind turbines.

No comments:

Post a Comment